For the slitting machine, it is very important to do a good job of tool adjustment, so how to do a good job of tool adjustment for the slitting machine?

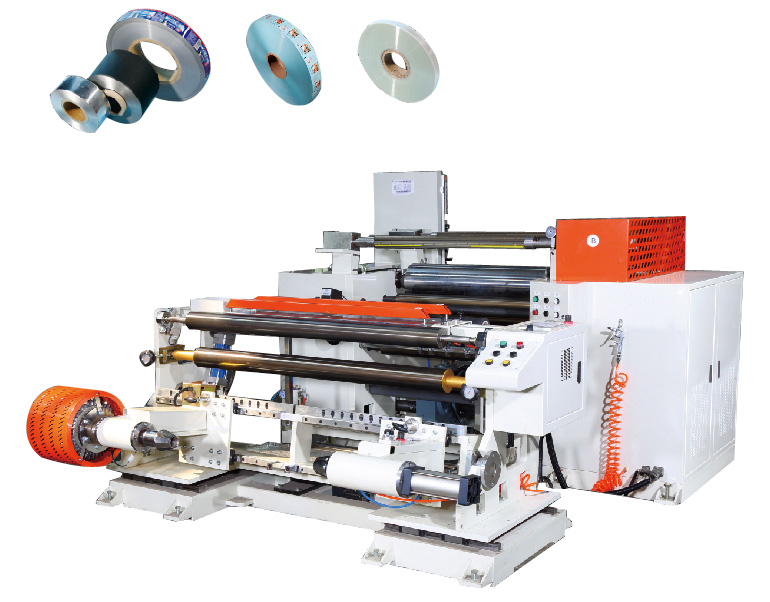

The cutter adjustment operation of the slitter is troublesome, time-consuming and laborious, and the gap between the cutters can not be accurately adjusted, which reduces the production quality of the product. The main feature of the slitter is that the magnetic particle clutch, as a resistance device, outputs a DC voltage through system control to control the resistance generated by the magnetic particle clutch. The main advantage is that it is a passive device, which can control small tension.

The non tangent slitting of the slitter is that the material has a certain wrap angle with the lower disc knife, and the lower disc knife falls to cut the material. This slitting method can make the material not easy to drift and has high slitting accuracy. However, it is not very convenient to adjust the knife. When the disc knife is installed, the whole shaft must be removed.

Therefore, these details should be done well when adjusting the cutter of the slitter.